Kelly Rose

Editor

Kelly Rose

Editor

DOES YOUR combination of workwear result in a serious risk to workers? And how do you know? Lakeland provides an insight.

A common PPE problem

EN and other PPE standards have undoubtedly meant improving workplace safety. Yet standards are not perfect. One challenge is that they generally address hazards and related PPE in isolation. By contrast, in the real-world safety managers often face multiple concurrent hazards and related PPE worn together. The problem comes when one item of PPE can affect the performance of another.

A dangerous example is found throughout the oil & gas industry. Users need FR or flash fire protective clothing as standard, but also need protection from chemicals. Or perhaps they might wear a disposable coverall over their primary FR clothing simply to keep it clean because FR protection can be expensive, and laundering can degrade FR properties.

A dangerous solution

Too commonly, the response is to wear a standard chemical suit or disposable coverall OVER an FR, EN 11612-certified garment. However, disposable coveralls and chemical suits are made of polymer-based fabrics which are flammable. In a flash fire, they can ignite and burn, sticking to the FR garment fabric, and continuing to burn – and transfer heat energy to the skin beneath - long after the flash fire is extinguished. The result can be a serious degradation of thermal protection.

That’s the theory. But is it proven?

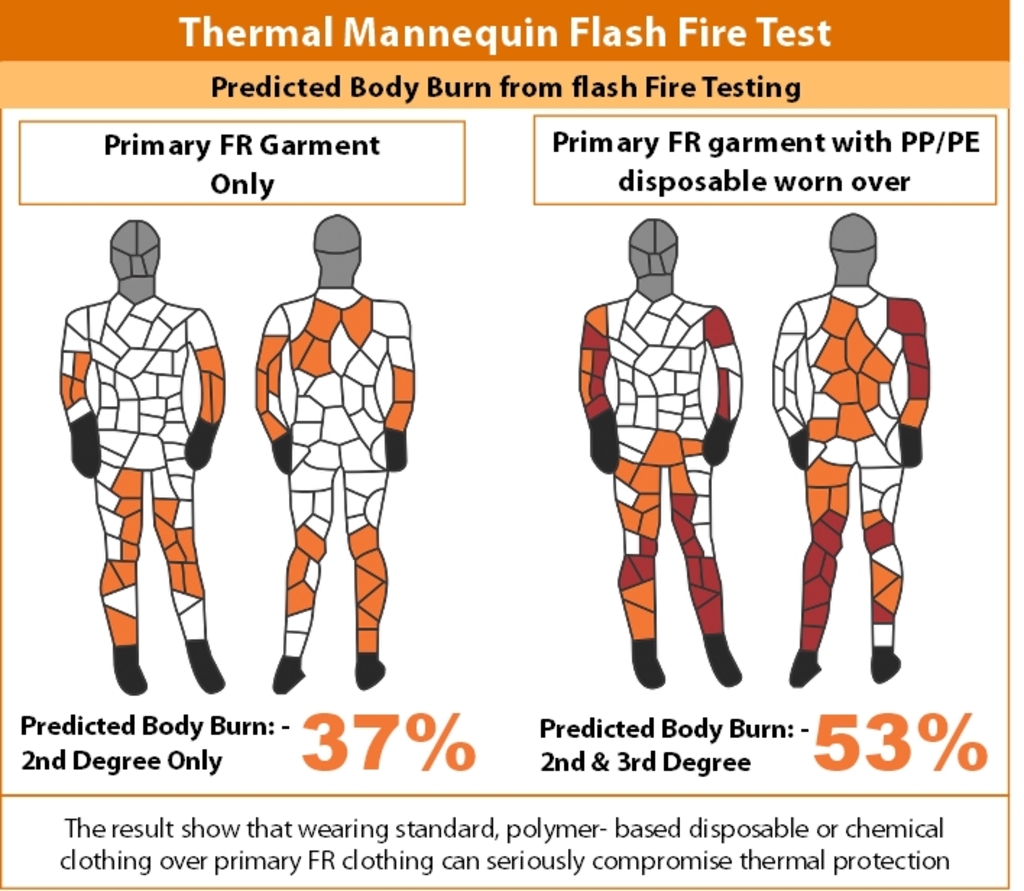

Yes. Thermal mannequin testing, referenced as optional in EN 11612 but mandatory in the US equivalent NFPA 2112, subjects FR garments to a simulated flash fire, producing a map of predicted body burn. In the image, the map on the left shows the predicted body burn (37% - 2nd degree only) for the primary FR garment. On the right is the result of the same test on the same primary FR garment with a standard PE/PP based disposable coverall worn over it. The effect is an increase in predicted body burn from 37% to 53% - beyond the 50% threshold commonly considered as the possible difference between life and death. (In the mandated NFPA 2112 version of this test the maximum allowable body burn is 50% for this reason). This proves wearing standard chemical or disposable clothing over primary FR workwear can create a serious hazard.

So, what can you do about it? The solution is properly selected Secondary FR (SFR) clothing. This is not designed to protect against fire, but to provide other protection when worn OVER primary FR clothing, but without compromising thermal protection.

The failure of PPE standards… and a new option.

The challenge for safety managers is that current standards simply fail to properly address this issue. In the US, NFPA 2113 (guidance on use and care of FR workwear certified to 2113) merely states overgarments should be “flame resistant”, without defining testing or what that means. Meanwhile EN 14116 requires a vertical flammability test, a useful indication that fabric and components are not flammable, but limited in that it fails to test SFR workwear in the way it is used – worn OVER primary FR clothing.

The only way to be sure that your SFR garment is not creating a hazard is through thermal mannequin testing to prove your combination of workwear does not increase body burn, as required by the new US standard ANSI 203.

ANSI 203 (2018) (ANSI is the American National Standards Institute which works to develop voluntary consensus for product standards) is specifically targeted at garments that may be worn over primary FR workwear. As well as flammability testing, it also requires two thermal mannequin tests: -

A test of a primary FR garment

A test of the SFR garment worn over the same primary FR garment

It requires that: -

Predicted body burn for the ensemble must be less than 50%

The body burn for the ensemble must not be more than 2% greater than the body burn for the primary FR garment alone.

So, ANSI 203 requires testing of SFR garments in the way they are worn in the real world, ensuring that the combination you have does not constitute a hazard.

While ANSI 203 is a US standard with no requirement to adhere to it in Europe or anywhere else, I would suggest that, even if not followed precisely, users wearing any combinations of two layers of workwear where one is Primary FR, should as a minimum, require manufacturers to provide thermal mannequin testing to prove their clothing does not degrade FR protection and increase body burn.

Meanwhile, Lakeland will be raising this shortcoming of PPE standards and pushing for EN to adopt a standard for SFR workwear like ANSI 203.

You can discover more about this issue and the solutions currently available (including Lakeland’s Pyrolon disposable workwear, providing Type 3 to 6 chemical protection and proven through thermal mannequin testing to be effective), in our recent blog. Through April and May we will be publishing informative content considering issues relating to this very common challenge of dealing with multiple hazards, so why not register for updates on new content. You can read the blog and register here.

Lakeland Industries Europe Ltd

Units 9-10 Jet Park 2

244 Main Road

Newport

East Yorkshire

HU15 2RP

UNITED KINGDOM

01430 478140