Ian Hutcheson weighs up the Total Cost of Ownership of

limited life and reusable gas-tight chemical protective suits

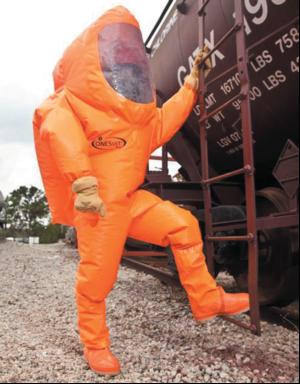

In emergency situations, the use of

fully encapsulated gas-tight chemicalprotective

suits is standarIan Hutcheson weighs up the Total Cost of Ownership of

limited life and reusable gas-tight chemical protective suits

In emergency situations, the use of

fully encapsulated gas-tight chemicalprotective

suits is standard for

monitoring and inspecting the scene as

well as mounting rescue, containment or

clean-up operations. The first choice to

be made in regards to gas-tight chemicalprotective

suits is between limited life and

reusable suits, both of which have similar

safety standards and application areas as

set out by the EN 943-2 certification.

When making this choice ,value for money

has been a common theme as managers try

to squeeze already tight budgets. Limiting

expenditure for new equipment without

sacrificing safety requires informed decision

making.

Too often, the purchase decision is made

on list price alone, but this is just one

portion of the entire cost. The Total Cost of

Ownership (TCO) analysis is a more useful

method for comprehensively determining

the full costs of chemical-protective suits as it

considers indirect costs such as maintenance

and repair costs, which can have a dramatic

impact on the overall spend and lead to

unanticipated budget over-runs.

Direct costs

Acquisition Price

While list price should not be the sole

consideration, it obviously is the starting

point of any cost analysis. The average

price for a reusable suit is €2500-€4000

while a limited life suit runs €1000-€1500.

Indirect factors

Inspection and recertification

To guarantee safety, regular inspection is

crucial for suits intended for multiple

uses, and these inspections have costs that

need to be considered in a TCO analysis.

Reusable suits generally have a shelf life of

5 to 10 years and must be inspected

annually by the manufacturers, which

costs €250-€500 per suit.

The inspection process can take two to

three months and requires additional

investment for replacements suits to

ensure preparedness. Add the cost of

shipping and logistics and inspection and

recertification can be an expensive exercise.

For limited-life suits, inspections are

only needed if the suit has been removed

from its package but not exposed to

chemicals, for example in a false alarm.

Here, inspection procedures are

straightforward as the suit simply needs a

visual inspection and a pressure-test to

ensure it's gas-tight. This operation can be

performed by emergency personnel

themselves or at cost of €100-150 by the

suit providers. If a limited-life suit is

contaminated, it must be disposed of (see

Disposability below).

Most suit usage takes place in practice

sessions, making it advisable to dedicate

suits to training to minimise the cost of

replacing or reinspecting suits that have

never been used in real action.

Maintenance and repair

The repair cost for both limited-life and

reusable suits varies depending on what

needs to be fixed, ranging from €50 to

patch a small cut to many hundreds of

Euros or more. If a suit is significantly

impaired, it may not be worth repairing as

the cost may exceed the acquisition price.

Cleaning

Cleaning of reusable suits is necessary for

personal hygiene reasons and this requires

cleaning areas, access to liquid and

detergents, and drying rooms. As cleaning

is a much less regular occurrence with

limited-life suits, the same work and

infrastructure requirements are not needed.

Storage

Due to their thick, often rubber-like

material composition, reusable suits

typically need to be laid flat or hung since

repeated folding may cause stress-cracking

or seam tape delamination. A large

amount of space is required for storage,

which can be costly and inconvenient.

Limited-life suits are typically lighter,

more flexible and take up significantly less

room so they can be stored folded in their

original package and removed anytime in

a ready-to-use condition.

Disposability

The disposal process for limited-life and

reusable suits is much the same. Both will

need to be decontaminated before

disposal. Once limited-life suits have been

contaminated they must be disposed of

whereas reusable suits can be inspected and

reused. However, it's possible that reusable

suits may need to be destroyed if it's too

risky to decontaminate or costly to repair.

Other factors to consider

Factors, such as user comfort and safety,

cannot be given a monetary value but are

an essential consideration.

For example, the lighter the suit, the

less arduous it is to wear. Some limitedlife

suits, weigh less than their reusable

counterparts and can offer more flexibility.

On the subject of safety, certified

options exist for both types of suits, and

the weighing of various performance

criteria such as flex-cracking and flame

and puncture resistance may need to be

taken into consideration.

Summary

When purchasing chemical-protective

suits, a TCO analysis can be a useful tool to

reveal an accurate picture of overall cost.

Ian Hutcheson is marketing and development

Manager for Saint-Gobain Performance

Plastics