Kelly Rose

Editor

Kelly Rose

Editor

Durnbury Limited were recently chosen to install the Compressed Air and Dust Extraction systems at the new Ben Ainslie Racing Headquarters in Portsmouth.

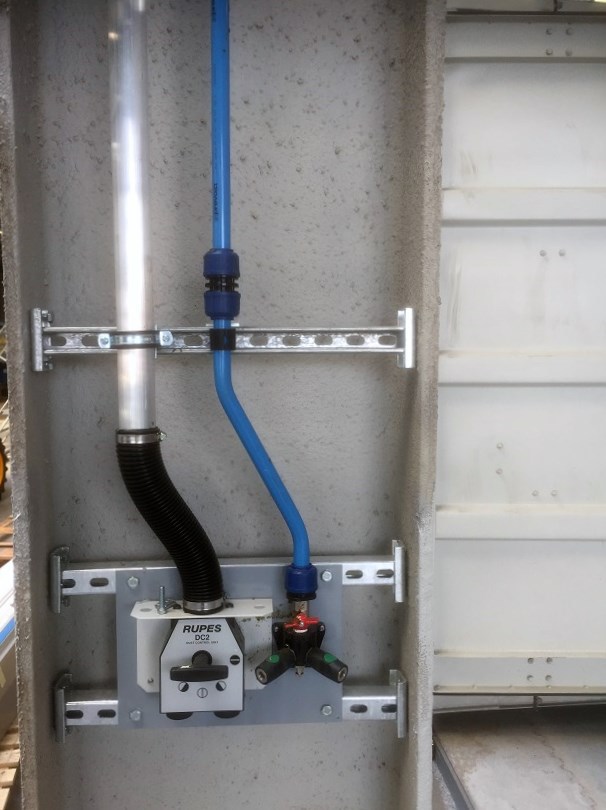

The Compressed Air System is comprised of a 22kw efficient variable speed compressor complete with internal air dryer providing clean dry air for powering air tools and spraying equipment.

The air is sent around the workshop via a new powder coated blue smooth bore rigid aluminium compressed air ring main terminating with quick release safety air couplers for connecting the air tools.

To keep sanding dust to a minimum Durnbury installed a Centralized Dust Extraction System comprising of an energy efficient Hi Vac Turbine with inverter system.

The dust is extracted directly from the tool head via a combined dust/air hose fitted to the dust modules. It then travels to the Turbine via a smooth bore rigid aluminium pipe system. Once it reaches the Turbine area the dust passes through an ATEX pre-filter and is collected in the collection bin for safe disposal. The Hi Vac Unit is connected to the compressed air system for automatic cleaning of the collection filters by air pulsing during the cleaning cycle.

30 First Avenue

Bluebridge Industrial Estate

Halstead

CO9 2EX

UNITED KINGDOM

01787 475351