Kelly Rose

Editor

Kelly Rose

Editor

SINCE THE emergence of the Covid-19 pandemic, PPE has rarely been out of the news. As a major manufacturer of the type of protective clothing commonly used in front line protection this ongoing discussion of PPE has highlighted a major confusion in the industry which has long been a source of concern.

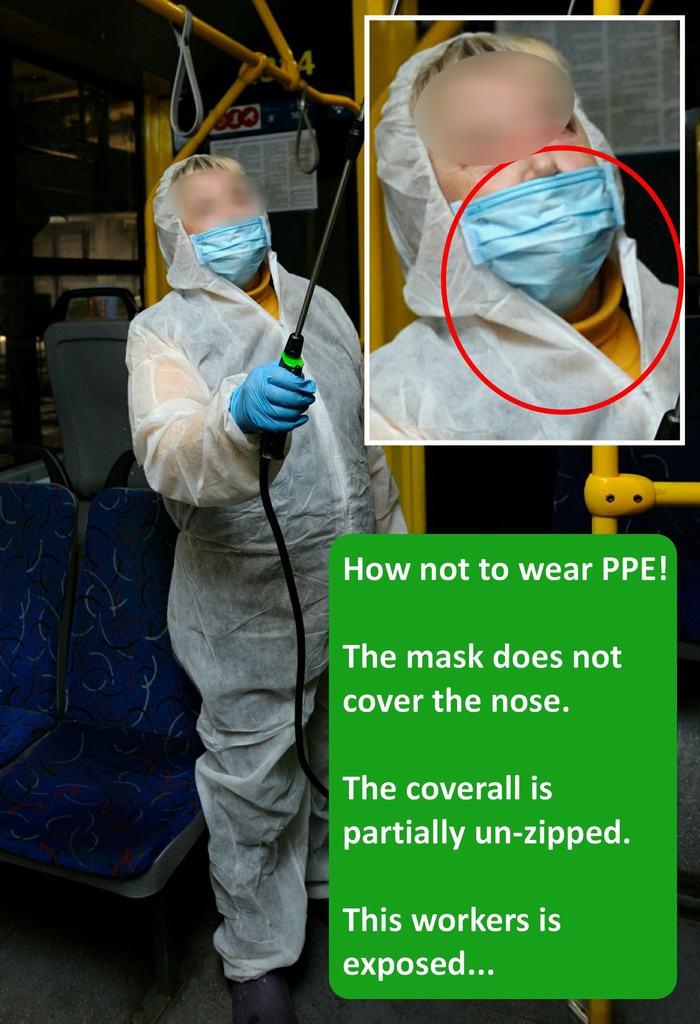

Meeting the huge growth in demand as a result of Covid-19 is one thing; ensuring users are wearing the correct protection and are wearing it properly when they get it is quite another. After all, availability of PPE becomes largely academic if the PPE available is not actually doing the job of protection it should.

The PPE industry is replete with misunderstandings, misinterpretations and myths, and our new ebook “Ten More PPE Myths” addresses ten of them; you can download it for free from the link below.

However, in the case of clothing to protect against infectious agents such as Covid-19 there are a number of challenging issues: ensuring selection of appropriate clothing; establishing proper donning and doffing procedures to minimise risk; achieving the best combination of protection and comfort and establishing and maintaining training to ensure wearers understand the risk and hazard; all contribute to ensuring protection is as good as it can be. But it is the very common misunderstanding and misrepresentation of the important EN 14126 standard that has been an ongoing cause of concern.

What is EN 14126?

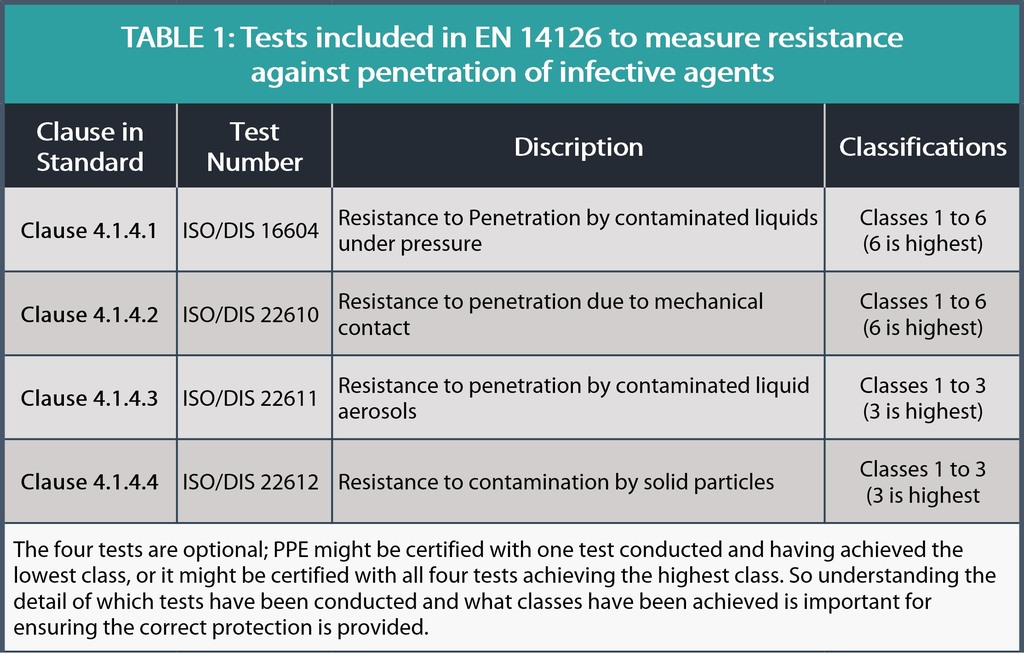

EN 14126 is the standard for clothing to protect against infectious agents. It defines four specific tests that assess a fabric’s ability to resist penetration by a virus via different routes. The results of each are classified according to tables given in the standard (either classes 1 to 3 or 1 to 6 depending on the test) – with the highest number indicating the highest level of resistance. These tests are shown in the Table 1.

So where is the confusion?

These tests are optional: a garment may be certified with only one conducted or all four. So the first challenge is for users to understand it is important not just to ensure a garment is certified but that the fabric has undergone the test(s) appropriate to their particular application and that a suitable classification has been achieved.

However, a second more dangerous confusion comes from the fact some manufacturers quote a test and classification that is not one of those listed in the standard and should not be used at all!

The Importance of and confusion over ISO 16604

Of the four tests, ISO 16604 is perhaps the most critical in many applications. It measures fabric resistance to penetration of pressurised liquids (such as body fluids) contaminated with pathogens. It uses a surrogate virus – bacteriophage Phi-X 174 - suspended in a “broth” to challenge the fabric at different pressures. A culture is grown to indicate if there has been penetration of the virus or not with results classified 1 to 6, with 6 being the highest class – indicating increasing pressure at which “strikethrough” occurs.

This is a complex, time consuming and expensive test; it might require testing at the lowest pressure, growing a culture, then testing at the next pressure, growing another culture… and so on all the way up to the highest class. So to reduce the time and work involved the standard also lists another test, ISO 16603, a version using a synthetic blood and simple visual assessment of penetration, in order to indicate a starting pressure for conducting ISO 16604.

And here is the confusion; the standard is quite clear (Clause 4.1.4.1 if you wish to check it for yourself) that ISO 16603 is ONLY to be used as a “screening” test for ISO 16604 and that the associated classification table ONLY applies to results of the ISO 16604 test; there is no classification table for ISO 16603 because it is not intended to indicate any level of protection or form part of certification.

Despite this, some manufacturers and users of protective clothing continue to detail or specify PPE with a classification for the ISO 16603 test. In other words, a classification that does not exist, and based on a test that is not intended to be used as any indication of protective performance.

Correcting this common error is not just an academic exercise. Use of the wrong test to classify protective clothing could result in front line health workers not being protected as they should be. The possible consequences are real and potentially catastrophic. Consider the fact that there is a substantive difference in the two tests; the same fabric will appear to have a much better result on 16603 than it will achieve on 16604. Thus, incorrect use of 16603 can create a false impression of the level of protection provided suggesting that it is higher than it really is. Consider the implications of that…

How can we clear up the confusion?

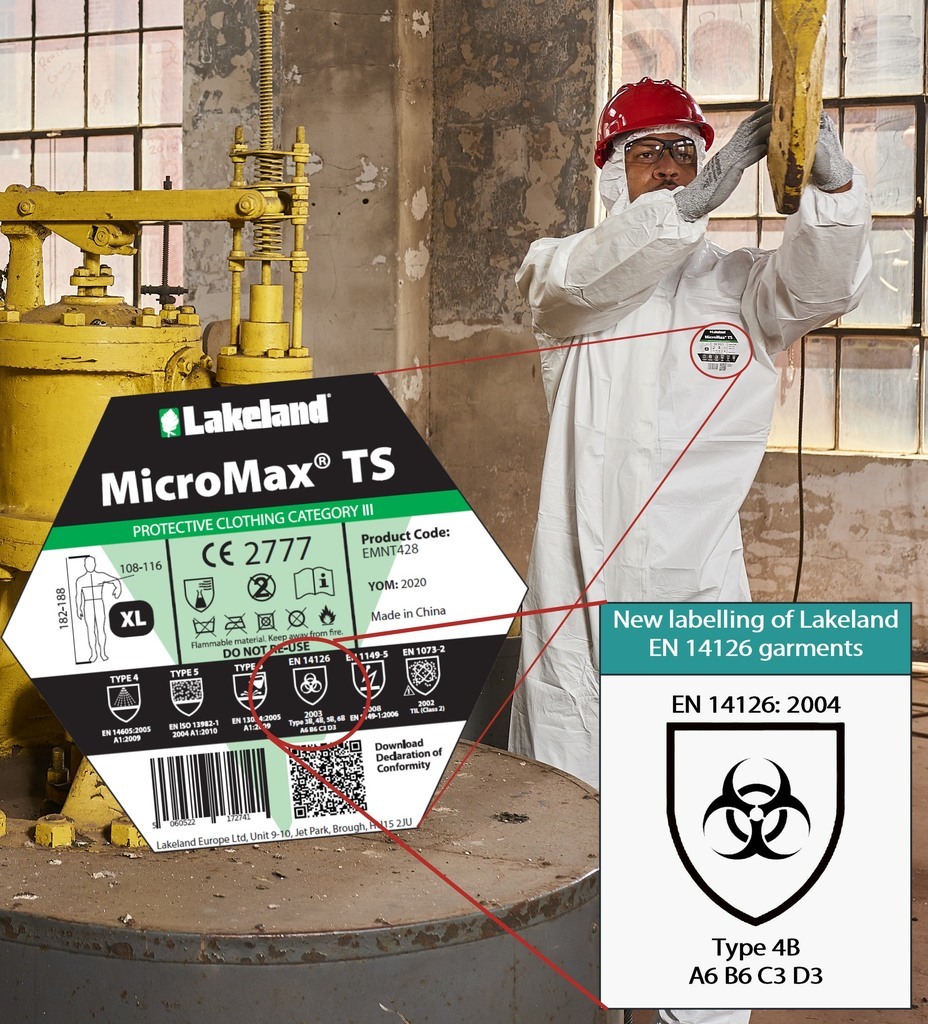

To address the problem a positive move will be to make the test information more accessible and transparent rather than burying it in User Instructions, data sheets or web sites. With this in mind, Lakeland has introduced a new system of labelling for EN 14126-certified garments.

In future, Lakeland garments will include the specific test results and classification on the label alongside the pictogram with the four tests being denoted by the letters A to D and associated results represented by the numbers 1 to 6 (or 3). So “A6” would indicate a class 6 in the all-important ISO 16604 test. You can read more about this labelling system in our blog here.

The first stocks of these garments will be delivered to European customers shortly. We have also proposed to the relevant PPE work group that the system should be introduced as a requirement in the next review of EN 14126. Though any such change is likely to take time - if it happens at all.

However, we feel it is self-evidently a very sensible change, so we challenge all manufacturers of EN 14126 clothing to also introduce it in the interests of clarity and transparency and for the benefit of users.

This misunderstanding of EN 14126 is just one of many confusions and myths in the PPE industry. You can read about more such myths in our new ebook which can be downloaded for free.

Lakeland Industries Europe Ltd

Units 9-10 Jet Park 2

244 Main Road

Newport

East Yorkshire

HU15 2RP

UNITED KINGDOM

01430 478140