Kelly Rose

Editor

Kelly Rose

Editor

EN 14126 is the key standard for protective clothing against viral and bacterial contamination. It is a complex and misunderstood standard and here, Martin Lill explains the standard.

PROTECTION AGAINST contamination by biological agents is a global issue. Between the 2014 Ebola outbreak, bird flu, and the devastating consequences of Covid, “PPE” has moved from being an obscure acronym to being a commonly used term. (Frustrating for those of us in the industry who found family, friends and just about everyone else suddenly became an expert in PPE!).

Images of the white “bunny suits” previous only seen in TV detective series now abound. But how are such garments assessed? How do you know a fabric will prevent contamination? As with other workplace hazards, biological or “infectious agent” protective clothing is managed by a European PPE standard, EN 14126. Unfortunately, as with many standards, it is complex and widely misunderstood. Thus, below, is a definitive guide to this standard and what it means.

What are you protecting against?

Infectious agents come in a variety of shapes & sizes. There are four overall types: bacteria, viruses, fungi, and parasites. Whilst bacteria are living organisms that multiply in the body, causing a range of health problems, viruses are fragments of DNA attached to a protein. These enter and infect individual cells in the body, using the cell’s replication system to reproduce.

Since both bacteria and viruses generally enter the body via the eyes, ears, nose, and mouth, why wear protective clothing? The answer is to prevent contamination of clothes or skin, so avoiding hands then transferring it to the face (hence the need to wash hands frequently and avoid touching your face).

Viruses are in general much smaller than bacteria and are measured in nanometres (a nanometres is 1 x 10-9 Metres – or one billionth of a metre). The smallest may be no more than 25 nanometres. The SARS-COV-2 virus is approximately 100 nanometres across, (for scale, the point of a pin is approximately 125,000 nanometres across, so the Covid virus is around 1250 times smaller than the point of a pin!). This is far smaller than most garment fabrics (or, for that matter, masks) can prevent passage of, so how come these types of PPE do provide some protection?

Viruses generally transfer from one body to another attached to either particles or droplets of moisture (such as those exhaled when breathing or coughing) which are considerably larger than the virus itself. The need therefor is to prevent passage of these rather than the virus itself. It’s a little like preventing passage of people in a car. You just need to stop the car, not the people in it (and the virus cannot get out and walk!).

What does EN 14126 assess?

The standard’s title is:

“Protective clothing – Performance requirements and test methods for protective clothing against infective agents”

It consists of four test methods (actually, the standard includes five – but we’ll come to that), each assessing the ability of the fabric to resist penetration of contaminated carriers in different circumstances.

The results of each test are classified according to tables given (two as Classes 1 to 3, with 3 the highest, and two as 1 to 6, with 6 the highest). A certified garment must have been tested to at least one of these tests and achieved at least a Class 1 result.

The four tests, along with the classifications, are shown in Table 1

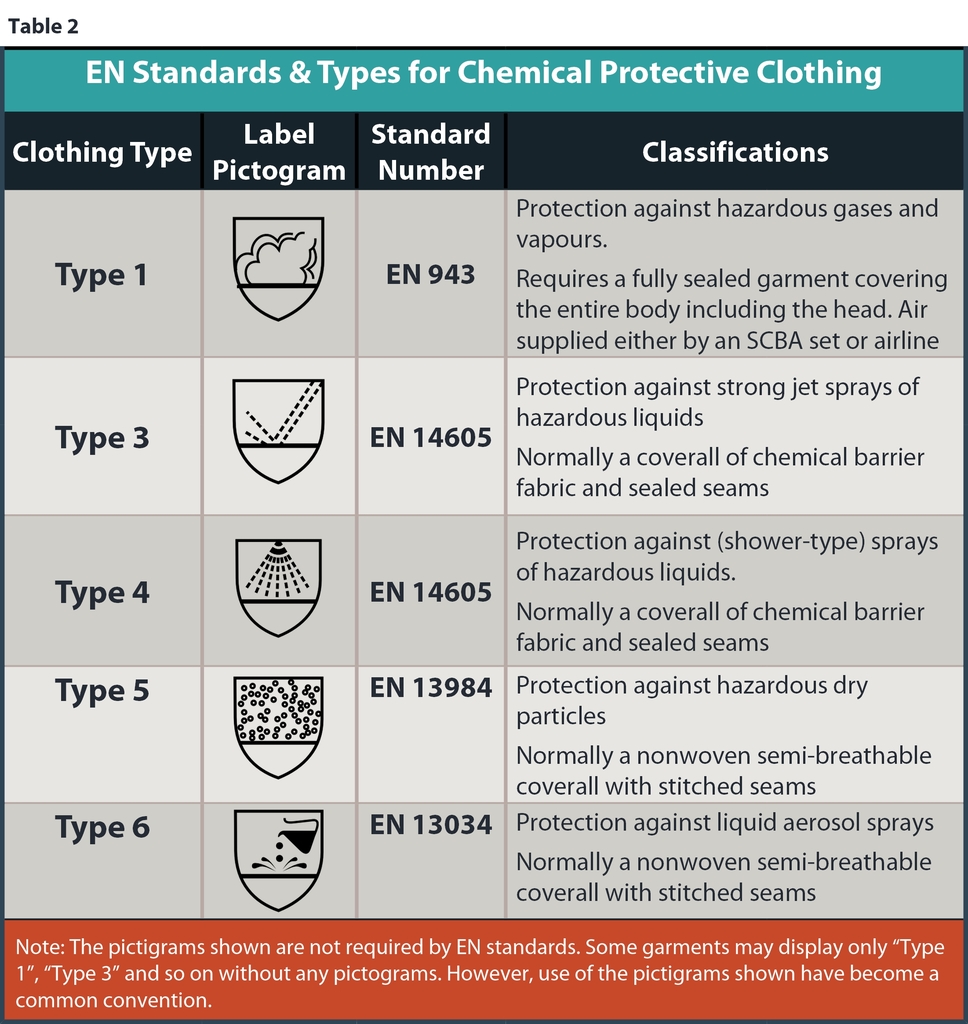

These tests measure fabric resistance, not performance of whole garments. Whole garment design is defined by the relevant chemical protection certification. EN standards define 5 Types of chemical protection (Types 1 to 6, but Type 2 was removed in 2015). The type of protection relates to: -

Type of hazard: particle, liquid or gas

Type of liquid spray: aerosol, liquid spray or jet spray.

The testing and requirements for each defines garment construction (for example, whilst Type 5 and 6 garments use stitched seams, anything above must have a sealed seam. (For more information on chemical protective clothing Types read our blog here.

The 5 chemical protective clothing types are shown in Table 2.

How do you identify certified protective clothing?

Certification of a garment to the EN 14126 standard is indicated by a specific pictogram on the label, though whilst confirming the garment is certified it gives no information about test results achieved. This can be found in accompanying user instructions (though at Lakeland, we introduced a voluntary labelling system which does provide this information on the label).

In addition, the chemical clothing Type is given the addendum “-B” to indicate certification to EN 14126. Thus, certification to EN 14126 and to chemical protective clothing Type 6 will be indicated on the garment label, as shown in Figure 1.

How is the correct garment selected?

Full understanding of the EN 14126 tests and the chemical protective clothing types provides a good framework for garment selection and relates to three key questions: -

Which EN 14126 tests are relevant?

Is the agent transmitted in a liquid or droplet (such as a body fluid)? Is it carried on a dust particle? Does the application involve contact with a contaminated surface? And so on. Decide which tests are relevant to your application and ensure the chosen garment has been subjected to those tests.

What classification do I need?

What test result classifications do you need? This might relate to identified hazardous viral load or to the relative danger of the hazard. A safe, “catch-all” route would be to simply require a class 6 on all relevant tests.

What are the garment construction requirements according to chemical protective clothing?

What chemical protective clothing Type does the application demand? In many cases the hazard is transferred via airborne particles or droplets so a Type 6 garments might be suitable. In the case of ebola, patient care includes a risk of sprays of body fluids, so at least a Type 4 garment, with sealed seams, might be more appropriate.

As with all hazard protection final PPE selection should follow a risk analysis which includes an assessment of the hazard and which may take priority over all other considerations. For example, if you are protecting against dry particles the obvious choice is a Type 5 garment. But if the virus involved is especially dangerous, even full gas tight Type 1 protection might be appropriate.

Confusion over the Mysterious Fifth Test

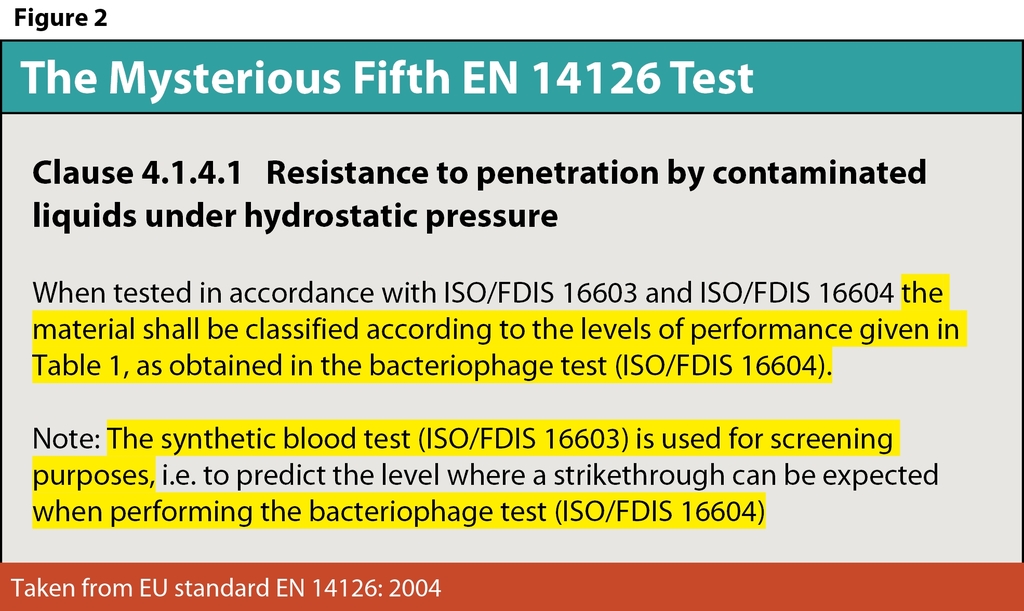

Whilst EN 14126 specifies four tests, it does mention a fifth – which has been incorrectly quoted by some manufacturers. The offender is ISO/FDIS 16603, a close relative of ISO 16604, the test that should be quoted. So, where does this mysterious fifth test come from?

The relevant clause in the standard is replicated in Figure 2 below. I have highlighted the key parts.

Standards are not always easy to understand. But this is clear. The first part states the fabric should be classified according to table 1 (the table is not reproduced here) using results from ISO/FDIS 16604 (the “bacteriophage test”). The second part states that ISO/FDIS 16603 is a screening test used only to identify a starting point for ISO/FDIS 16604.

The important test is ISO/FDIS 16604. It is an exacting test, measuring resistance to penetration of contaminated liquid at a range of pressures from zero to 20kPa (Class 6 is achieved when no penetration occurs at 20kPa), and using a liquid infected with a real bacterium (bacteriophage Phi-X174).

The test involves maintaining the contaminated liquid in contact with the fabric and at the specified pressure, sampling the opposite surface and growing a culture to identify contamination. Undertaking this at the six different classification pressures is a costly and time-consuming process.

By contrast, ISO 16603 is a basic test using synthetic blood and a visual assessment. It is not therefor an effective indicator of bacterial penetration, and its sole purpose is to provide a quick method of identifying the pressure at which “strikethrough” might occur, thus providing a starting point for ISO/FDIS 16604, and potentially saving considerable time and cost. This is the only reason it is mentioned in the standard.

Yet some manufacturers continue to quote classifications according to results obtained in ISO/FDIS 16603 as if it was relevant. Why? You would have to ask them, but I have no doubt it results from simple misinterpretation of the standard, and the fact that often a poor classification according to ISO 16604 is accompanied by much better (though false) “classification” from ISO 16603, has absolutely no relevance. (And incidentally, the fact that the same fabric achieves different results is proof that the tests are not equivalent).

Whatever some manufacturers or organisations claim, the standard is clear. The test that should be used and quoted is ISO 16604. ISO 16603 is purely a screening test and should not be used as an indication of protection.

Conclusions

Correct understanding of EN 14126 is vital in ensuring adequate protection. In choosing protective clothing for infectious agent hazards, following a robust risk assessment: -

Ensure the EN 14126 tests relevant to the application have been conducted and that the classifications achieved are suitable

Ensure the correct garment chemical protective Type is chosen and that therefor the design and construction is appropriate

Do not be mislead by the use of ISO 16603. It is not a substitute for ISO 16604. The standard is clear that it is used as a screening test only. In fact, using a classification based on ISO 16603 is using a classification that does not exist.

For more information on all types of protective clothing, including regular educational and informative blogs, subscribe to the Lakeland blog https://blog.lakeland.com/europe

Martin Lill is director - International marketing at Lakeland Industries. For more information, visit www.lakeland.com

Lakeland Industries Europe Ltd

Units 9-10 Jet Park 2

244 Main Road

Newport

East Yorkshire

HU15 2RP

UNITED KINGDOM

01430 478140