Kelly Rose

Editor

Kelly Rose

Editor

TOO OFTEN users ignore issues of garment design and construction in selection of chemical hazmat clothing – often because of cost. The consequence is missing out on the clear benefits that effective design can bring, and the possibility that operators are not adequately protected.

While EN standards have undoubtedly brought benefits in the form of improved levels of safety in a range of industries, there have also been drawbacks. Arguably, knowledge of the hazard and the PPE needed to protect against it has been somewhat substituted by the simple process of ticking the “is it certified to the standard?” box. Every sales representative in the industry will recognise the PPE negotiation that consists of only two questions: “Is it certified?”, and “How much is it?”.

The result is that less attention is paid to quality of PPE beyond certification. Standards ensure only that PPE meets minimum performance requirements, so exclusive focus on certification means aspects such as product design, quality and so on are given less credence, reducing the likelihood that users will pay more for product that exceeds those minimum requirements. In turn this makes it more difficult for manufacturers to sell higher quality product and therefor to justify developing it. The danger is that over time the results is a levelling down of PPE quality and design to the lowest common denominator – that needed to achieve the minimum requirements defined in the CE standard.

It would be a curious approach indeed (not to say dangerous) to target minimum protection for your workers. Many applications require more than the minimum defined in a standard, so exclusive focus on it can result in PPE that meets it but is not actually adequate for the application. Such is the case with chemical protective clothing. Many garments on the market consist of very basic designs with minimal features that just meet the requirements of standards but do not necessarily provide the best, or even adequate (for the task), protection.

Furthermore, this focus on certification can mean missing out on the clear benefits that better design and features can bring, and opens the door to the risks that better quality avoids. Garment design is a critical issue for both comfort and durability and ignoring it may compromise both.

Providing the best protection means optimising the combination of protection, comfort and durability. These last two may seem like unnecessary luxuries, but both are safety issues because an uncomfortable garment is less likely to be worn properly and a less durable garment may burst or split at a key moment. In both cases, protection is compromised. So, users ignore the elements of garment design that go beyond certification to standards at their peril.

What elements of design and construction of chemical suits brings benefits in terms of protection, comfort and durability?

A well-designed garment can bring real benefits. Aspects to consider include: -

Additional Garment Features

To ensure protection, developers of chemical suits must consider how they will effectively coordinate with other PPE such as gloves, mask, boots or other equipment.

A three-piece hood design creates a more 3-D shape, allowing better head movement without compromising visibility, and enabling better fitting to the rim of a respiratory mask

To discover the 8 must have features to look for in your chemical suit click here

In conclusion, it is vital to look beyond the issue of whether a chemical hazmat suit (or any other item of PPE) is certified to the required standard. Many garments in the market do indeed meet the requirements of a standard, and yet lack enhanced construction and design features, falling well short of providing wearers with good, or even adequate, protection.

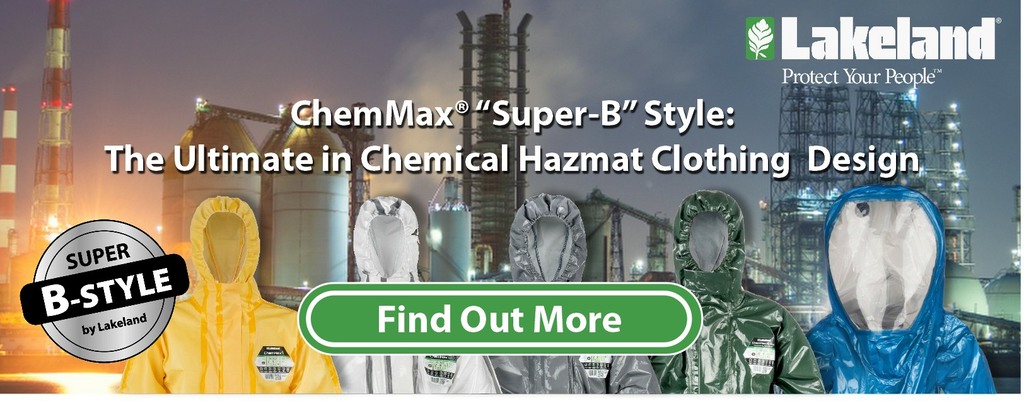

Lakeland ChemMax chemical suits are manufactured using the unique “Super-B” design. An ergonomic suit founded on Lakeland’s four decades experience in the design and development of chemical protective clothing. “Super-B” was developed with the wearer in-mind and optimises the combination of protection, comfort and durability.

You can read more about the benefits of the Super-B ChemMax suits in our blog where you can also download a free infographic showing the key elements f the perfect chemical hazmat suit.

Lakeland Industries Europe Ltd

Units 9-10 Jet Park 2

244 Main Road

Newport

East Yorkshire

HU15 2RP

UNITED KINGDOM

01430 478140