What is D3O?

D3O is a British based impact protection solutions company that markets a unique patented technology, which is used to produce a superior shock absorbing material.

How does it work?

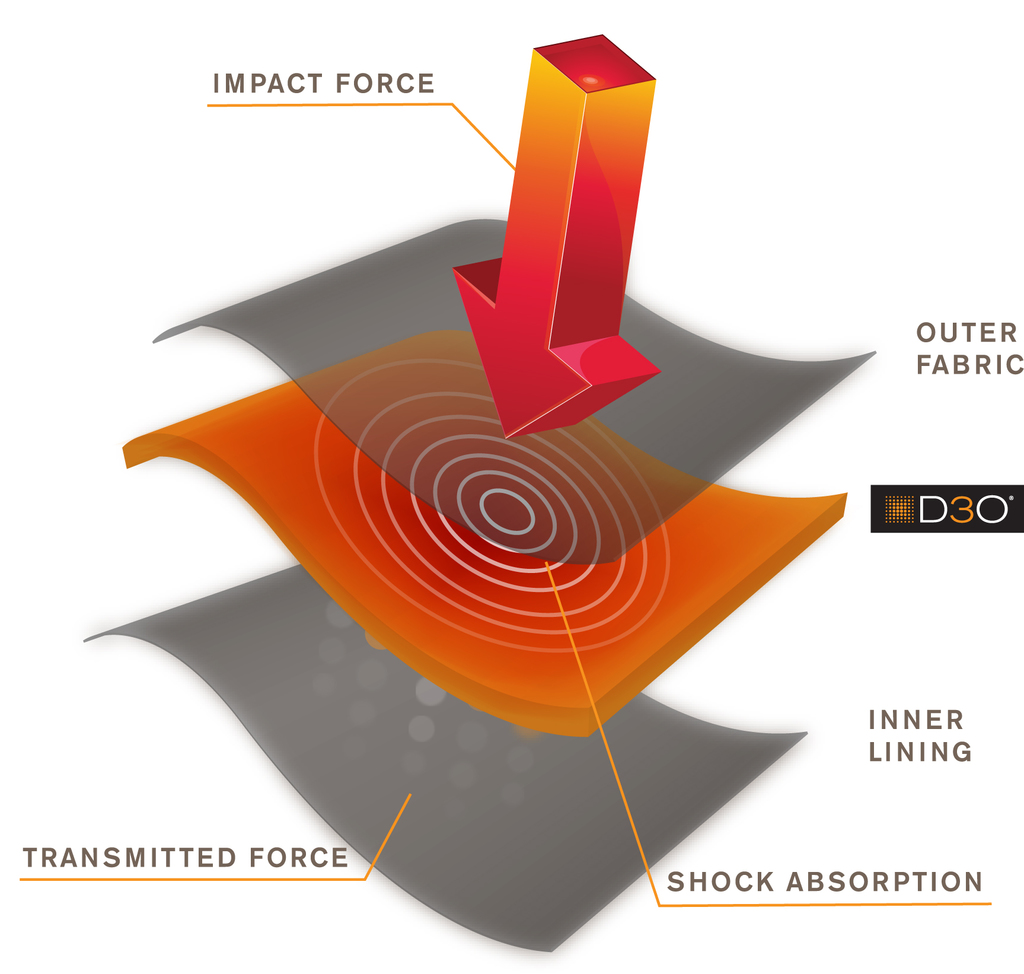

D3O manufactures a smart material with high shock absorbing properties. In standard conditions, the molecules flow freely allowing the material to remain soft and flexible, but on impact, they lock together to absorb impact energy and reduce the force transmitted. The molecules instantly return to their flexible state.

The material is strain rate sensitive which means the stronger the impact, the more the molecules react, and better the protection.

Does the material go hard on impact?

No. D3O does not go hard when hit, but the molecules lock together to absorb and spread the force, significantly reducing the effect of impact.

Which markets is D3O used in?

D3O develops impact protection solutions for a range of markets from motorcycle to electronics, sports to footwear, as well as the military and PPE. We work exclusively with Tech 21 in the electronics sector, who use D3O in their range of smartphone and tablet cases.

How is D30 different to hard protection?

D3O reacts to the unique impact environment e.g. at high speeds it provides a different level of impact to at low speeds.

D3O absorbs and dissipates the impact energy which reduces the force transmitted.

It delivers the most flexible and discreet protection on the market and it consistently outperforms traditional foam based materials.

How can something so thin/low-profile offer a higher standard of protection?

D3O’s unique molecular properties means it can remain thin and flexible, while providing optimum protection against impact.

What is D3O Smart Skin?

D3O Smart Skin is a low-profile, soft and flexible protection system which allows for D3O’s unique patented technology to be heat-bonded directly on to fabric. It is a cost-effective solution by simplifying the garment manufacturing process by removing the need to sew protective padding into pockets. D3O Smart Skin is compatible with all of D3O’s materials. The first versions feature D3O Aero which is a lightweight, soft material ideal for sports.

What D3O products are there?

Current D3O impact protection solutions include:

• Limb protectors (knee, elbow, shoulder, hips)

• Hand protectors (knuckle, palm, finger)

• Back protectors

• Footwear solutions: metatarsal, insole, strobel board and ankle protectors as well as a range of materials suitable for mid-soles for athletic and industrial/military.

• Electronics casing (create by Tech21 including mobile phone, tablet, laptop)

• Covert impact jacket, used by military and law enforcement

• D3O Smart Skin (heat bonded direct to garments)

• D3O solid sheet and mesh available in different thicknesses

D3O also works with partners on PDAs to create bespoke impact protection and shock absorbing solutions.

How is it tested?

D3O tests its materials and components using the highest standard of testing. We run our own in-house tests, which are then verified by independent laboratories, such as SATRA, STR, NPL, INSPEC, HPE, MERL, BSI.

What is the goo?

The D3O technology is a composite material, comprising polymers and dilatant fluid. The D3O dilatant contributes greatly to the behaviour you may have observed in various videos or at trade shows (i.e. when hit with a hammer, the material appears to go ‘hard’). It is not practical to use the dilatant on its own, since it is liquid and very heavy. However, by combining it with different polymers and some enhanced chemistry to form D3O technology, it is possible to produce various solid shapes, encompassing the properties of both, dilatant and polymer materials.

How does the dilatant become a D3O component?

The dilatant is heavy and not practical to use on its own and this was D3O’s challenge – how to integrate the properties of the dilatant into a solid, elastic 3D shape? D3O’s team of experts was able to create flexible, lightweight, impact protection solutions by incorporating the dilatant fluid into various polymers via a combination of chemical and process engineering. How we achieve this however, is top secret and remains the expertise of D3O.

How is D3O used?

It has a wide range of applications, including personal protection for various sport disciplines, motorcycling, work wear, and accessories for electronic protection, such as iPhone cases and computers. We have also developed the D3O Covert that was originally designed as a blunt force impact vest for the French Gendarmerie.

How is D3O made?

D3O has an in-house team of chemists and designers, who customise the material for bespoke protection.

We offer full 360 degree solutions for our partners, such as Furygan, from brainstorm, idea generation, CAD concepts, prototyping, testing, sampling to production.