Kelly Rose

Editor

Kelly Rose

Editor

Dusty conditions commonly associated with the storage and handling of grains and powders can potentially lead to dangerous explosions.

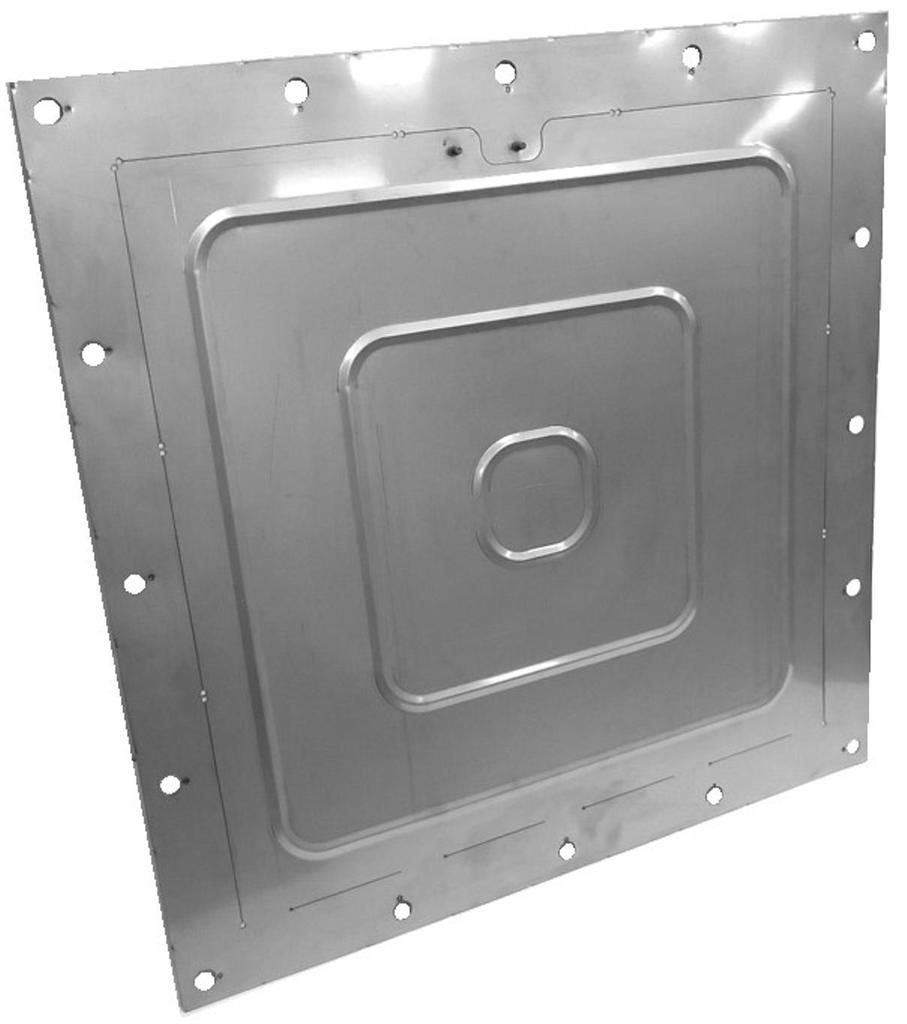

The robust construction of Elfab’s ribbed explosion venting panel ensures that operational excellence is maintained when low to medium levels of vacuum are present. As part of Elfab’s latest range of explosion protection solutions, this design can withstand vacuum or backpressure of up to 40% of the minimum burst pressure, making it suitable for many standard applications, such as silos and bucket elevators.

As a maintenance-free, non-torque sensitive explosion protection solution, the ribbed explosion vent, according to Elfab, is proving to be one of the most economic and efficient panels on the market, with its distinctive low profile, space-saving design. The low installation and storage costs mean it is one of the most cost effective options available.

The ribbed explosion vent is available with the optional benefit of an integral burst detection system for instantaneous notification when panel has functioned. Elfab’s ATEX-approved burst detection system, Vent-Tel, was specifically designed for its range of explosion venting panels to further ensure onsite safety for its customers. It is now also available with the industry’s first GSM (Global System for Mobile Communication) explosion vent burst alert system.

Alder Road

West Chirton North Industrial Estate

North Shields

NE29 8SD

UNITED KINGDOM

0191 293 1234