Why should kitchen extract ductwork be kept clean, and why must heating,

ventilation and air conditioning (HVAC) ductwork be kept in good

condition? What other health and safety considerations surround air

conditioning and ventilation ductwork maintenance? The prime driver for

kitchen extract ductwork is fire safety, and it falls within the

Regulatory Reform Order (2005) and insurers’ requirements.

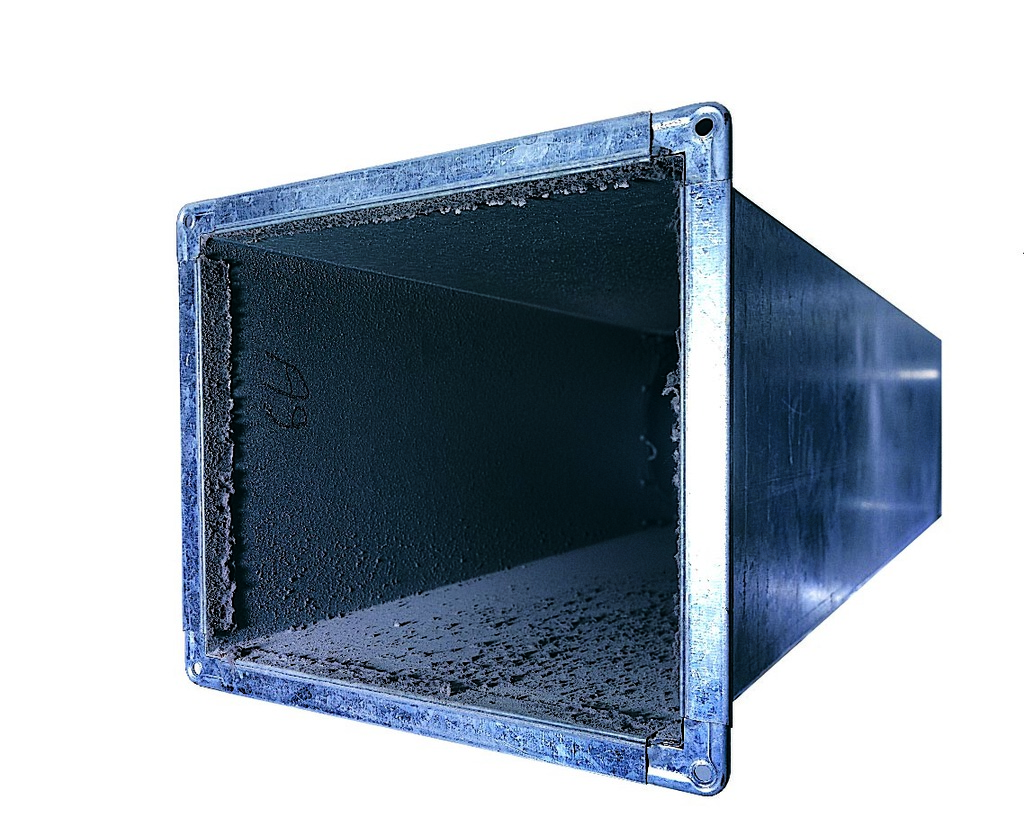

The

grease that inevitably accumulates within the duct system forms a

hidden combustion load. There are ready sources of ignition in a kitchen

and the duct system perfectly funnels oxygen. One of the big problems

is that the ductwork that connects the kitchen canopy to the fan for

discharging heat, smells and fumes to atmosphere is typically hard to

access and easy to ignore. When grease and oil is ignited, the ductwork

can spread flame and heat through the building like a fuse.

Super-heated

ductwork may ignite nearby combustible materials - hot or burning oil

can spread fire from small leaks and flame at the discharge can light up

a roof. Sometimes, the path of the fire is difficult to predict and

firefighters can lose valuable minutes tracing out the implications of

fire discovered in a building.

There are standards available, such

as the Building and Engineering Services (B&ES) Guide to Good

Practice TR19: Cleanliness of Ventilation Systems. This advocates

cleaning 'when necessary' and describes measurement techniques, such as

the wet film thickness test, to define when a system should be cleaned.

In the absence of such measurement, the advice defaults to time based

maintenance, as suggested in this Table.

Air Ductwork

For

HVAC ductwork, the prime drivers are health, comfort and wellbeing, and

this is underlined in the Workplace (Health Safety & Welfare)

Regulations, as updated in 2014. The Regulation 6 ACOP 51 states:

"Mechanical ventilation systems (including air-conditioning systems)

should be regularly and adequately cleaned. They should also be properly

tested and maintained to ensure that they are kept clean and free from

anything which may contaminate the air.”

British Standard

EN15780: Ventilation for buildings — Ductwork — Cleanliness of

ventilation systems describes the various cleanliness quality classes of

building and the appropriate frequency of inspection and cleanliness

standards to be achieved.

Table A.1 — Typical applications of cleanliness quality classes

Quality Class

Typical examples

Low

Rooms with only intermittent occupancy, e.g. storage rooms, technical rooms

Medium

Offices,

hotels, restaurants, schools, theatres, residential homes, shopping

areas, exhibition buildings, sport buildings, general areas in hospitals

and general working areas in industries

High

laboratories, treatment areas in hospitals, high quality offices

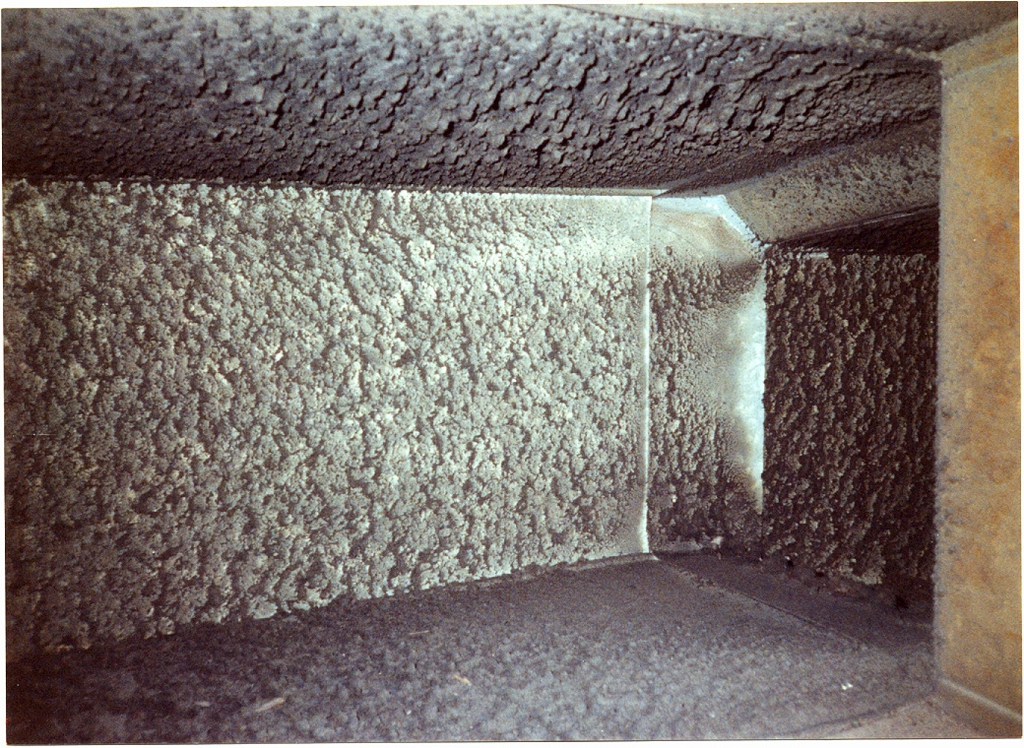

Again,

B&ES TR19 provides further detail on how to measure

cleanliness/dirtiness and suggests good practice techniques for remedial

works.

Often, the relatively complex procedures for inspection,

monitoring and measurement of cleanliness or dirtiness serve to support

common sense assessments, which are carried out by simply viewing the

duct interior. However, the measured standards are useful in cases of

uncertainty as to whether a system needs cleaning.

Increasing

interest from employers, developers and academics is focused on the

productivity gains from relatively small expenditures on improving the

working environment. The World Green Building Council’s recent report on

health, wellbeing and productivity, supported by heavyweights, such as

Jones Lang LaSalle, Skanska and Lend Lease, makes the point that there

is overwhelming evidence that demonstrates that the design and

maintenance of an office impacts the health, wellbeing and productivity

of its occupants. It goes on to describe the costs of proper maintenance

as trivial compared to staff costs.

Fire Damper Testing

Fire

damper testing is another aspect of heating, ventilation and air

conditioning maintenance that health and safety professionals need to

deal with. Fire dampers are essential life safety components that shut

in the event of fire to prevent the spread of fire from one compartment

to another via ductwork. British Standard 9999 (2008) Annex W1 mandates

regular testing of these systems to ensure that they operate properly.

This is crucial in a fire situation, and experience shows that a

significant number of dampers may fail in practice.

-ENDS-

Editor’s

note:

System Hygienics is a member of the Hotchkiss Group, which

provides specialist services in ductwork contracting, fire resistant

duct systems, ventilation products and accessories, and fire resistant

and acoustic ductwork coating.

For further information, visit HYPERLINK "http://www.systemhygienics.co.uk" www.systemhygienics.co.uk

Issued on behalf of: Issued by:

System Hygienics Limited PRG Marketing Communications

Chaucer Industrial Estate 10 Gildredge Road

Dittons Road Eastbourne

Polegate BN21 4RL

BN26 6JF

Michaela Bailey

Tel: 01323 411044

michaela@prgltd.co.uk

www.prgltd.co.uk

01323 481170onlineenquiry@systemhygienics.co.uk