Its application engineers use CAD software and specialised data to develop springs that are optimised for each application.

In car seat applications, when a vehicle is involved in an accident, the inertia of the mechanism that enables the forward and backward adjustment may allow the seat to be released from its track. By using a spring to overcome the forces that release the mechanism, the seat remains secure. William Hughes designs and manufactures a number of springs for such critical applications. Most are manufactured from hard drawn wire with a phosphate coating and the finished parts are stress relieved in a bid to ensure the performance is maintained.

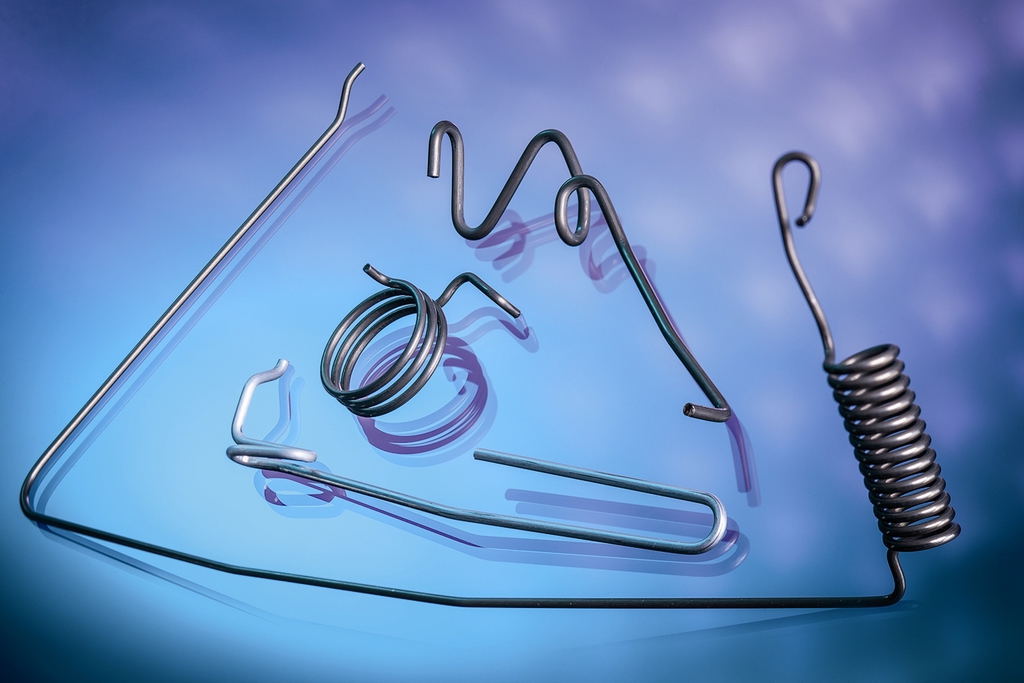

The company also manufactures torsion springs for the mechanisms that raise and lower the seat and can supply a range of bent wire forms and sub-assemblies for car seats and trim panels. Seat cushion frames are welded or clipped together and supplied as complete pre-assembled units.

01963 363377sales@wmhughes.co.uk